The electric motors operate on magnetism. The amount of current needed to create magnetism depends on the size and design of the motor. Motors are rated in horsepower or watts. The higher the rating of the motor, the higher the starting and running currents will be.

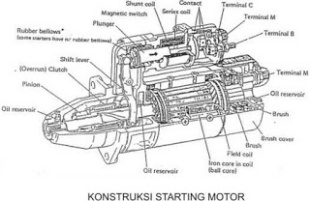

Motor Starting is a vital component inside the starting system. Without the starting motor, the engine can’t be worked. Motor starting converts electrical energy through a battery into mechanical rotating energy. These motor work under heavy load. The main function of motor starting is to move the flywheel movement for starting the engine. The picture below illustrates about the motor starting construction. They produce big power in a short time and in a small volume. In addition, if the starter motor fault occurred, the device can’t be run, especially in emergency devices.

Figure 1.1 Motor Starting Construction

- Full Voltage Starting Of AC Induction Motors

A full voltage or across the line, starter is designed to apply full line voltage to the motor upon starting. Full voltage starters may be either manual or magnetic.

Manual Starter

Manual starters are often used for small motors, those up to about 10 hp. They consist of a switch with one set of contacts for each phase and a thermal overload device.

Magnetic Across The Line Starter

This is operated by an electromagnetic or a solenoid. A manual starter must be mounted so that is easily within reach of the machine operator. With magnetic control, push button stations are mounted nearby, but automatic control pilot devices can be mounted almost anywhere on the machine.

- Reduced Voltage Starters

There are two primary reasons for using a reduced voltage when starting a motor :

- It limits line disturbances.

- It reduces excessive torque to the driven equipment.

When a reduced voltage is applied to a motor rest, both the current drawn by a motor and the torque produced by the motor are reduced

- DC Motor Control

Direct current (DC) motors are used far less than AC units (they need special starting equipment). With a DC magnetic motor starter, it’s important to realize that the breaking of the power circuit produces an arc, which will burn the power contacts if not extinguished quickly. To help extinguish the arc, the starter is equipped with three power contacts connected in series.

- Electric Clutch

In general, an electric clutch consists of an electromagnet disc and an armature disc

Electric clutches are usually used to :

o Engage very large motors to their loads after the motors have reached running speeds.

o Provide smooth starts for operations in which the material being processed might be damaged by abrupt starts.

o Start high inertia loads when starting may be difficult for a motor that is sized to handle only the running load.

References

Petruzella (1996). Industrial Electronics.Singapore: McGraw Hill.

Murugesan V. M., Chandramohan G., Senthil Kumar M., Rudramoorthy R., Ashok Kumar L., Suresh ,Kumar R.,Basha D. and Vishnu Murthy K.(2012).”Overview Of Automobile Starting System Faults and Fault Diagnosis Methods”. Journal of Engineering and Applied Sciences.7.812-819.